|

|

|

|

|

|

|

|

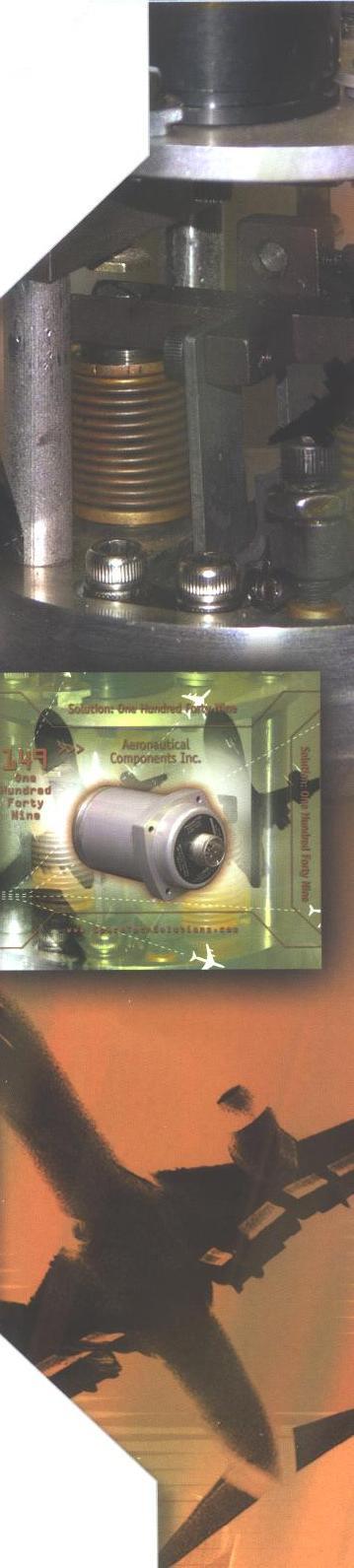

From 'Out of the Blue' ASR Comes to the Rescue Obviously, when it comes to aircraft parts, quality and safety are always top concerns. No one knows this better than the folks at Aeronautical Components Inc., a Long Island-based manufacturer of military aircraft parts. When the U.S. government tightened the standards on an oil pressure transmitter manufactured by Aeronautical Components, company officials knew they would have to make some changes for the part to be included on the updated Qualified Parts List (QPL).

Michael Dantona, marketing and engineering manager at Aeronautical Components, was a part of the team challenged with making the necessary changes to the part. "The part in question is a rather complicated pressure bellows located inside a transmitter that senses oil pressure inside the aircraft's engines," said Dantona. "Our existing design did not meet the QPL's new performance parameters, so we had a challenge on out hands and weren't sure where to turn for help."

Fortunately, Dantona heard about SATOP through the Long Island Forum for Technology. "We didn't know a thing about SATOP and were scratching our heads about how to resolve the bellows issue, when out of the blue SATOP came to the rescue," he said.

Dantona filled out a Request for Technical Assistance (RTA) and was matched with ASR Corp., a premier mechanical engineering services company. Mike Costen, a principle engineer and Keith Frerichs, an analyst with ASR, agreed to tackle Aeronautical Component's RTA.

"Although the part had failed with the new specs, Aeronautical Components wanted to make the necessary changes to become a qualified supplier," said Costen."Keith and I decided to start with a comprehensive stress and fatigue analysis."

ASR ended up examining three to four different bellows configurations, ultimately offering one design with a high degree of confidence that it would pass the test.

"Aeronautical Components did not have the expertise to create the re-design required to pass the newest performance parameters," explained Costen, "but this is exactly the type of work we do at ASR." Dantona has taken the new bellows design to a manufacturer and is optimistic that it will meet the new performance requirements.

"The whole process of working with SATOP was painless and rewarding," said Dantona. "It was remarkable that we could be associated with ASR's level of engineering technology, and we didn't have to pay for it - I would gladly recommend the program to other manufacturers."

"Even though I've answered more than a dozen SATOP requests, I haven't gotten tired of the challenges," said Costen. "They are usually interesting projects, that have short and sweet solutions. There is something deeply satisfying in solving clearly identifiable problems."

SATOP New York Director Ryan Mclaughlin said that the Aeronautical Components RTA clearly illustrates the need for a program like SATOP. "Here is a successful company facing a technical challenge that could have a negative impact on their business," he said. "Through SATOP, they were able to access the high-level technical expertise of Mike and Keith at ASR and receive a cost-effective solution. That's why SATOP exists - to help small businesses succeed and grow by overcoming technical challenges."

|

|

|